Sponge Media™

Sponge-Jet has engineered a line of composite abrasives, incorporating the best abrasives or micro-abrasive particles within high-performance synthetic sponge. The diverse range of recyclable composites provide superior results for aggressive profiling and abrading or delicate cleaning on highly sensitive substrates. The synthetic sponge captures up to 95% of the contaminants, reducing fugitive emissions through its MicroContainment™ feature.

Blue Sponge Media ™

Part #: SJM-B

Non Aggressive

This Sponge Media product is designed for contaminant removal and absorption without the presence of moisture and without collision energy damage to delicate substrates.

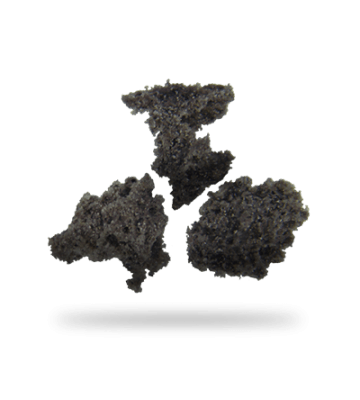

Garnet Sponge Media ™

Part #: SJM-GMA-GAR-3060

Moderately Aggressive

This value-oriented Sponge Media product provides reduced recyclability, making it a better choice where full media recovery is not possible.

Green Sponge Media ™

Part #: SJM-G

Lightly Aggressive

This Sponge Media product is designed for contaminant removal and absorption without the presence of moisture.

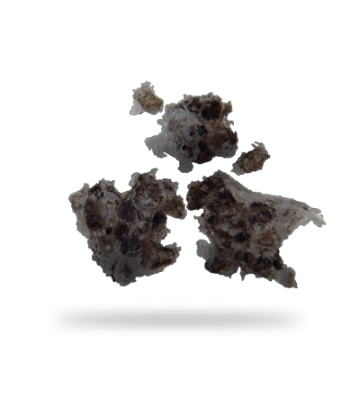

Silver 120 Sponge Media ™

Part #: SJM-S-120

Moderately Aggressive

This Sponge Media product is for light industrial surface preparation where selective coating and corrosion removal is required and where minimal profile is specified.

Silver 16 Sponge Media ™

Part #: SJM-S-16

Highly Aggressive

This is the third most commonly used Sponge Media for industrial coating removal and surface preparation. Silver 16 Sponge Media is ideal when a very coarse, angular profile is specified for the coating that is to be applied.

Silver 220 Sponge Media ™

Part #: SJM-S-220

Lightly Aggressive

This Sponge Media product is for sensitive industrial surface preparation, the resurfacing of existing coatings or delicate substrate treatment.

Silver 30DG Sponge Media ™

Part #: SJM-S-30DG

Highly Aggressive

The fine particle size of this Sponge Media product allows for more uniform treatment of detailed surfaces and increased production. Silver 30DG Sponge Media™ abrasive recyclability is lower; ricochet and dust are more pronounced compared with standard Sponge Media products.

Silver 320 Sponge Media ™

Part #: SJM-S-320

Lightly Aggressive

This Sponge Media product is for sensitive industrial surface preparation, the resurfacing of existing coatings or delicate substrate treatment.

Silver 320 DG Sponge Media™

Part #: SJM-S-320DG

Lightly Aggressive

The fine particle size of this Sponge Media product allows for more uniform treatment of detailed surfaces and increased production. Media recyclability is lower; richochete and dust are more pronounced compared with standard Sponge Media products.

Silver 500 Sponge Media ™

Part #: SJM-S-500

Lightly Aggressive

This Sponge Media product is for HIGHLY sensitive industrial surface preparation or for the resurfacing of existing coatings. It provides maximum, delicate substrate treatment while still attaining ISO / NACE / SSPC cleanliness grades.

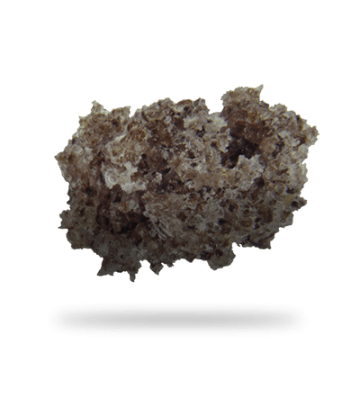

Silver 60 Sponge Media ™

Part #: SJM-S-60

Moderately Aggressive

This Sponge Media product is the 2nd most commonly used for industrial coating removal and surface preparation. It is ideal when a moderate, angular profile is specified for the coating to be applied.

Silver 60 DG Sponge Media™

Part #: SJM-S-60DG

Moderately Aggressive

The fine particle size of this Sponge Media product allows for more uniform treatment of detailed surfaces and increased production. Media recyclability is lower; ricochet and dust are more pronounced compared with standard Sponge Media products.

White Glass Bead Sponge Media ™

Part #: SJM-GL-6080

Lightly Aggressive

This Sponge Media product is for the preparation of soft alloys and a low-build coating system is specified.

Whiste Plastic Sponge Media™

Part #: SJM-WP-3040

Lightly Aggressive

White Plastic Sponge Media™ is designed to remove an applied coating without etching/profiling steel or aluminum substrates.

Features

Safer for workers:

- Less worker exposure and fatigue

- Less eye and other injuries

- Contains no Crystalline Silica

- Contains no detectable Beryllium

Better for the Environment

- Clean, Dry, Low Dust reusable abrasive

- Extremely low dust generation compared to ordinary abrasives

- High Reuse (recycles)

- Lower fugitive emissions

Improved Operational Efficiency

- Enhanced visibility and first-pass quality

- Fewer defects and rework, keeping projects on schedule

- High-quality surface preparation in sensitive or confined areas

- The ability for other trades to work nearby

- A solution for preparing surfaces near finished coatings, instruments and equipment

- Contains no thermal Plastics ( Ideal for Pulp and Paper Mills)

Lower Direct and Indirect Costs

- Low inbound and outbound freight

- Less pollution, waste generation, fines and reporting

- Improved community relations

- Less liability, litigation and compliance reporting

- Less downtime

- Improved asset availability

- Coatings perform longer, saving on future maintenance and acquisition costs

- Easier staging, containment, ventilation and clean up

- Less waste, disposal and material handling

- Greater production and efficiency

- Increased profits and production